6 speed manual transmission diagram

Six-speed manual transmissions offer a compelling blend of driver engagement and efficiency, showcased in models like the Tremec and GM 6T30/6T40 families.

These transmissions, often detailed in diagrams and manuals, are experiencing a resurgence among automotive enthusiasts seeking a connected driving experience.

What is a 6-Speed Manual Transmission?

A 6-speed manual transmission is a mechanical gearbox with six forward gear ratios, allowing drivers to manually select the optimal gear for various driving conditions.

Unlike automatic transmissions, it requires the driver to operate a clutch pedal and shift lever, providing a direct mechanical connection between the engine and wheels.

Diagrams illustrate a complex system of gears, shafts, and synchronizers. These components work in harmony to transfer power efficiently.

The six speeds offer a wider range than older transmissions, improving both acceleration and fuel economy.

Understanding the internal layout, often depicted in service manuals, is crucial for maintenance and repair.

Why are 6-Speed Manuals Still Relevant?

Despite the rise of automatics, 6-speed manuals remain relevant due to their engaging driving experience and driver control. Enthusiasts appreciate the direct connection and ability to precisely manage power delivery.

Diagrams reveal the mechanical simplicity, appealing to those who enjoy understanding and maintaining their vehicles.

Furthermore, manuals often offer better fuel efficiency and lower initial cost. The resurgence in enthusiast cars, like the Corvette with Tremec’s 6-speed, demonstrates continued demand. Manuals provide a visceral connection lost in many modern vehicles, as illustrated in online forums and technical guides.

Core Components of a 6-Speed Manual Transmission

Key components, visible in detailed diagrams, include gear sets, shift forks, synchronizers, and input/output shafts, working in harmony to deliver power efficiently.

Gear Sets and Ratios

Gear sets are fundamental to a 6-speed manual transmission, illustrated clearly in a transmission diagram. These sets dictate the vehicle’s speed and torque output, offering a wide range of ratios for optimal performance. Each gear pair, meshing precisely, transmits power from the input to the output shaft.

The ratios themselves are carefully calculated to balance acceleration, fuel efficiency, and top speed. Lower gears provide increased torque for quick starts, while higher gears enable efficient cruising. A diagram will show how different sized gears achieve these varying ratios, impacting the overall driving experience and engine load.

Shift Forks and Selector Rods

Shift forks and selector rods are crucial components, visibly represented in a 6-speed manual transmission diagram. These mechanisms translate the driver’s gear selection into physical movement within the transmission. The selector rods connect the gear lever to the shift forks, which then engage the appropriate gear set.

A diagram illustrates how these rods and forks slide along grooves, precisely positioning the synchronizers to facilitate smooth gear changes. Their accurate operation is vital for preventing grinding and ensuring reliable power transfer. Proper alignment and minimal play are essential, as shown in detailed schematics.

Synchronizers: Ensuring Smooth Shifts

Synchronizers are key to the smooth operation of a 6-speed manual transmission, clearly depicted in a detailed diagram. These components equalize the rotational speed of the gears before engagement, preventing grinding and allowing for effortless shifts. A transmission diagram highlights the synchronizer’s cone-shaped surfaces and blocking rings.

They utilize friction to match speeds, illustrated in schematics, and are often double-cone designs for enhanced performance. Proper synchronizer function is vital for driver comfort and transmission longevity. A diagram will show their placement between the gear and the shaft, enabling seamless gear changes.

Input and Output Shafts

Input and output shafts are fundamental to a 6-speed manual transmission’s operation, prominently featured in any transmission diagram. The input shaft receives power from the engine’s clutch, while the output shaft delivers it to the driveshaft and ultimately, the wheels. A diagram illustrates their parallel arrangement and the gears they support.

These shafts are precision-engineered to handle significant torque and rotational speeds. The diagram will show splines for gear attachment and bearings for smooth rotation. Understanding their roles is crucial for diagnosing transmission issues, as depicted in service manuals and schematics.

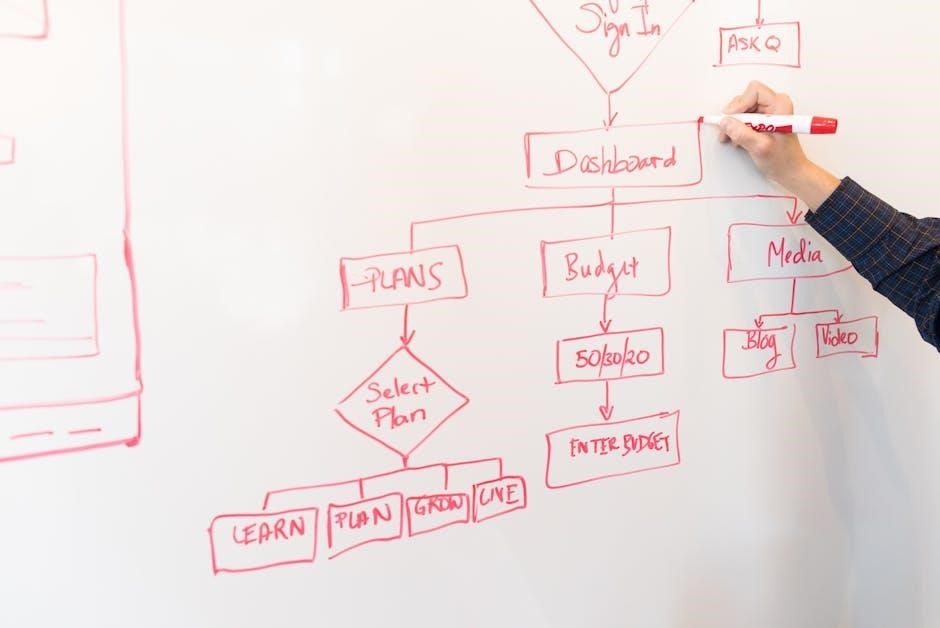

Detailed Diagram Breakdown

Detailed diagrams reveal the intricate arrangement of gears, shafts, and forks within a 6-speed manual, aiding understanding of power flow and component interaction.

Identifying Key Parts in a 6-Speed Manual Diagram

A 6-speed manual transmission diagram showcases crucial components like the input shaft, receiving power from the clutch. Gear sets, varying in size, dictate different ratios for acceleration and cruising. Synchronizers, vital for smooth shifts, are clearly visible, alongside shift forks and selector rods controlling gear engagement.

The output shaft transmits power to the driveshaft. Diagrams also highlight the housing, bearings supporting rotating parts, and the shift linkage connecting the lever to internal mechanisms. Understanding these parts, and their precise arrangement, is key to diagnosing issues and performing repairs. Detailed schematics often include exploded views for clarity.

Understanding Gear Mesh and Power Flow

A 6-speed manual transmission diagram illustrates how gear mesh dictates power flow. Input from the engine rotates the input shaft, transferring energy to selected gears. These gears then mesh with others, altering the rotational speed and torque delivered to the output shaft.

Different gear ratios provide varying levels of acceleration and efficiency. The diagram reveals how shifting engages different gear pairs, changing the power delivery. Understanding this process, visualized in the diagram, is crucial for comprehending how a manual transmission functions and maximizes performance.

Clutch System Integration in the Diagram

A 6-speed manual transmission diagram must depict the crucial role of the clutch. The clutch, positioned between the engine and transmission, controls power transfer. When engaged, it connects the engine’s rotation to the input shaft, initiating power flow.

Disengaging the clutch temporarily disconnects this link, allowing for gear changes. The diagram illustrates the clutch’s components – pressure plate, friction disc, and release bearing – and their interaction. Understanding this integration, visually represented, is key to grasping the manual transmission’s operation and smooth shifting.

Common 6-Speed Manual Transmission Models

Diagrams highlight popular models like Tremec units and the GM 6T30/6T40/6T45 family, frequently found in sports cars and performance vehicles.

These transmissions showcase varying internal layouts, best understood through detailed schematic representations.

Tremec 6-Speed Manual Transmissions

Tremec has become synonymous with high-quality aftermarket 6-speed manual transmissions, and their diagrams reveal robust construction. A recent offering, specifically designed for the C8 Corvette, demonstrates their engineering prowess.

Detailed diagrams showcase the internal gearsets, shift mechanisms, and housing designs that contribute to Tremec’s reputation for durability and precise shifting. These diagrams are invaluable for installers and enthusiasts alike. The company’s commitment to innovation is evident in their designs, often featuring advanced synchronizer technology. Understanding the diagram helps visualize power flow and component interaction, crucial for both maintenance and performance tuning. Tremec’s transmissions are frequently chosen for performance upgrades, and their diagrams aid in customization.

General Motors 6T30/6T40/6T45 Family

General Motors’ 6T30, 6T40, and 6T45 family of transmissions, frequently found in Chevrolet and Opel vehicles, are complex systems best understood with detailed diagrams. These diagrams illustrate the internal components, including the intricate valve body and planetary gearsets.

Diagrams reveal the location of the speed sensors and solenoids critical for operation. Common issues, like those with the speed sensor ring, are easily identified when referencing a schematic. Understanding the diagram aids in diagnosing problems and performing repairs. These transmissions, while reliable, can exhibit specific failures, and a diagram is essential for troubleshooting. Accessing these diagrams is vital for effective maintenance and repair procedures.

Applications in Sports Cars and Performance Vehicles

Six-speed manual transmissions are favored in sports cars and performance vehicles for their direct driver control and enhanced power delivery, often visualized through detailed diagrams. Tremec’s recent six-speed manual transaxle, designed for the C8 Corvette, exemplifies this trend, with diagrams showcasing its bespoke design.

These diagrams highlight the robust gearsets and optimized ratios crucial for high-performance applications. Understanding the transmission’s internal layout, as shown in a diagram, is vital for modifications and upgrades. Enthusiasts utilize diagrams to analyze power flow and identify potential weak points, ensuring optimal performance and reliability.

Typical Failures and Troubleshooting

Diagrams aid in diagnosing issues like gear grinding or clutch problems within a 6-speed manual, revealing internal component relationships and potential failure points.

Common Symptoms of a Failing 6-Speed Manual

A detailed diagram becomes invaluable when identifying the root cause of issues. Common symptoms include difficulty shifting into specific gears, often accompanied by grinding noises, which a diagram helps pinpoint to synchronizer issues.

Unusual noises, like whining or clunking, can indicate worn gear sets, visually confirmed with a transmission schematic. Clutch slippage or a spongy pedal feel, while not directly visible in a transmission diagram, often accompanies internal failures.

Fluid leaks, observable externally, may stem from seal failures shown on a parts breakdown. Finally, complete gear lockout signals a severe internal problem, necessitating a thorough inspection guided by a comprehensive diagram.

Diagnosing Gear Grinding Issues

A 6-speed manual transmission diagram is crucial for pinpointing gear grinding origins. Begin by referencing the diagram to locate synchronizer components for the affected gear. Grinding often indicates worn or damaged synchronizers, failing to match gear speeds during shifts.

Inspect the gear teeth themselves, using the diagram to identify their specific location and mesh points. Damage here suggests excessive wear or improper lubrication. Check shift forks and selector rods (shown on the diagram) for binding or misalignment, hindering smooth engagement.

Finally, verify proper clutch disengagement; incomplete disengagement exacerbates grinding.

Identifying Clutch Problems

A 6-speed manual transmission diagram aids in tracing clutch-related issues. Begin by examining the diagram’s depiction of the clutch assembly – pressure plate, disc, and release bearing. Slippage often stems from a worn clutch disc or a failing pressure plate, visible in exploded views.

Inspect the hydraulic or cable linkage (detailed on the diagram) for leaks, damage, or improper adjustment. These affect clutch engagement. A sticking or damaged release bearing causes noise and incomplete disengagement.

Check for fluid leaks around the master and slave cylinders, referencing the diagram for their locations.

Repair and Maintenance

A 6-speed manual transmission diagram is crucial for fluid changes, synchronizer replacements, and gear repairs, ensuring correct component placement and torque specifications.

Fluid Changes and Recommendations

Utilizing a 6-speed manual transmission diagram during fluid changes is paramount for locating the fill and drain plugs correctly. Regular fluid changes, typically every 30,000 to 60,000 miles, are vital for longevity.

Consulting the diagram helps identify the correct fluid type – often a specific GL-4 gear oil – as using the wrong fluid can cause damage. The diagram also illustrates the fluid level checking procedure, ensuring optimal lubrication.

Proper fluid levels prevent premature wear on gears and synchronizers, contributing to smooth shifting and overall transmission health. Always refer to the vehicle’s service manual alongside the diagram for precise intervals and specifications.

Synchronizer Replacement Procedures

A 6-speed manual transmission diagram is indispensable when undertaking synchronizer replacement, illustrating component locations and assembly order. Disassembly requires careful attention, referencing the diagram to avoid misplacement of parts.

Synchronizers, crucial for smooth gear changes, often fail due to wear. The diagram aids in identifying worn components and understanding their interaction. Specialized tools are often needed, and the diagram clarifies their application points.

Reassembly demands precise torque specifications, guided by the service manual and visualized with the diagram. Proper installation ensures optimal shifting performance and prevents future failures.

Gear Repair and Replacement

A 6-speed manual transmission diagram is paramount when addressing gear issues, providing a clear visual of gear meshing and shaft arrangements. Damage assessment requires careful inspection, often revealing chipped teeth or wear patterns. The diagram helps pinpoint the affected gear(s) and their corresponding position.

Replacement necessitates specialized tools for gear separation and installation, with the diagram illustrating proper alignment. Ensuring correct gear clearances is vital for quiet operation and longevity.

Repair, if feasible, demands precision machining; the diagram aids in understanding gear profiles; Reassembly must adhere to torque specifications, guided by the service manual and visualized with the diagram.

The 6T30 and 6T40 Transmissions (Chevrolet/Opel)

A 6-speed manual transmission diagram is crucial for understanding the internal workings of the 6T30/6T40, aiding in diagnosing common issues and repair procedures.

Specific Issues with 6T30/6T40 Units

Understanding a 6-speed manual transmission diagram is paramount when addressing the specific challenges of the 6T30 and 6T40 units. These transmissions, commonly found in Chevrolet and Opel vehicles, are prone to certain failures. A detailed diagram reveals potential weak points, such as the valve body, which can experience solenoid failures leading to erratic shifting.

Internal wear on components, visible in a schematic, can cause harsh engagement or slippage. The torque converter, also illustrated in diagrams, may develop issues. Furthermore, the transmission control module (TCM) can contribute to problems, and a wiring diagram is essential for troubleshooting electrical faults. Accurate diagnosis relies heavily on interpreting these visual guides.

Repair Solutions for Common 6T30/6T40 Problems

A 6-speed manual transmission diagram is invaluable when tackling 6T30/6T40 repairs. Valve body issues often require solenoid replacement or a complete rebuild, guided by the diagram’s component layout. Internal wear necessitates replacing clutches and steel plates, referencing the schematic for correct placement.

Torque converter failures demand replacement, while TCM problems may involve reprogramming or module exchange. A wiring diagram aids in diagnosing electrical faults. Thorough cleaning and inspection of all parts, as shown in exploded views, are crucial. Proper fluid changes, using the manufacturer’s specifications, are also essential for long-term reliability.

Advanced Features and Technologies

Diagrams reveal innovations like double-cone synchronizers enhancing shift quality, alongside computer-aided engineering optimizing gear designs for improved durability and performance.

Double-Cone Synchronizers

Double-cone synchronizers, clearly illustrated in detailed diagrams of 6-speed manual transmissions, represent a significant advancement in shift smoothness. Traditional synchronizers utilize a single cone to match the speeds of the gear and the shaft before engagement. However, double-cone designs incorporate two cones, providing a larger surface area and more progressive synchronization.

This results in faster, more precise shifts, reducing gear clash and wear. Diagrams showcase how the initial cone initiates speed matching, while the second cone fine-tunes it for a seamless connection. This technology is particularly beneficial in high-performance applications where quick gear changes are crucial, and is often found in Tremec transmissions.

Computer-Aided Engineering in Transmission Design

Computer-Aided Engineering (CAE) is now integral to designing modern 6-speed manual transmissions, as evidenced by detailed diagrams and simulations. CAE allows engineers to virtually prototype and analyze gear meshes, stress points, and lubrication systems before physical production. This minimizes costly errors and optimizes performance.

Diagrams generated through CAE reveal intricate details of gear tooth profiles and housing structures. Finite Element Analysis (FEA) identifies potential failure points, while Computational Fluid Dynamics (CFD) refines oil flow for cooling and efficiency. This technology is crucial for manufacturers like Tremec, ensuring durability and precision in their transmissions.

Future Trends in Manual Transmissions

Diagrams reveal potential adaptations for hybrid and electric vehicles, with manual transmissions offering unique driving experiences and efficiency gains.

Enthusiast demand fuels a resurgence, prompting innovation in 6-speed designs and integration with new powertrains.

The Resurgence of Manuals in Enthusiast Cars

Detailed diagrams of 6-speed manual transmissions are becoming increasingly relevant as these systems experience a notable revival within the enthusiast automotive community. A growing segment of drivers actively seeks a more engaging and connected driving experience, rejecting the convenience of fully automatic systems.

This trend is particularly evident in sports cars and performance vehicles, where precise control and driver involvement are highly valued. Manufacturers, responding to this demand, are incorporating 6-speed manuals – like those from Tremec – into new models, and even offering them as options in previously automatic-only platforms. The availability of comprehensive diagrams aids both mechanics and enthusiasts in understanding and maintaining these increasingly popular transmissions.

Hybrid and Electric Vehicle Manual Transmission Adaptations

Diagrams illustrating 6-speed manual transmissions are evolving as engineers explore their integration into hybrid and electric vehicle (EV) powertrains. While seemingly counterintuitive, a manual transmission can offer unique benefits in these applications, primarily enhancing driver engagement and potentially improving efficiency through optimized gear selection.

Adaptations often involve removing the direct connection to an internal combustion engine, instead utilizing the transmission to manage power delivery from the electric motor or hybrid system. This requires modifications to the transmission’s control systems and potentially the gear ratios themselves. The complexity is visualized through detailed schematics, aiding in development and maintenance.

Resources for Further Learning

Diagrams and technical manuals, alongside online forums, provide invaluable insights into 6-speed manual transmissions, aiding understanding of their complex internal workings.

Online Forums and Communities

Engaging with online automotive forums and communities is crucial for anyone delving into 6-speed manual transmissions. These platforms host a wealth of knowledge, often including detailed diagrams and discussions about specific models like the Tremec or GM 6T30/6T40.

Enthusiasts frequently share repair experiences, troubleshooting tips, and even annotated diagrams, offering practical insights beyond technical manuals. Searching for specific issues, like gear grinding or synchronizer problems, can quickly yield relevant threads and solutions.

Active participation allows you to ask questions, learn from experienced individuals, and contribute to the collective understanding of these complex systems. These communities are invaluable resources for both novice and experienced mechanics.

Technical Manuals and Service Guides

Comprehensive technical manuals and service guides are essential for understanding the intricacies of 6-speed manual transmissions. These resources provide detailed exploded diagrams, parts lists, and step-by-step repair procedures, crucial for accurate diagnosis and maintenance.

Look for manuals specific to the transmission model – Tremec, GM 6T30/6T40, or others – as internal components and procedures vary significantly. Diagrams illustrate gear mesh, shift fork operation, and synchronizer mechanisms.

Service guides often include torque specifications, fluid recommendations, and troubleshooting flowcharts, ensuring repairs are performed correctly and safely. Investing in a quality manual is paramount for successful transmission work.

Safety Precautions When Working on Manual Transmissions

Always disconnect the battery before working on any transmission. Securely support the vehicle with jack stands, and understand the diagram’s weight distribution.

Disconnecting the Battery

Before commencing any work on a 6-speed manual transmission, or referencing its diagram, disconnecting the vehicle’s battery is paramount for safety. This crucial step prevents accidental electrical shorts or activation of systems during disassembly or reassembly.

Begin by locating the negative terminal, typically marked with a (-) symbol. Use a wrench to loosen the nut securing the cable, then carefully remove the cable from the terminal. Tuck the cable away from the terminal to prevent accidental contact.

This simple precaution safeguards against potential damage to the vehicle’s electrical components and, most importantly, protects the technician from electrical shock. Always consult the vehicle’s service manual for specific instructions.

Proper Lifting and Support Techniques

When removing or installing a 6-speed manual transmission – even while referencing a detailed diagram – employing correct lifting and support techniques is vital for both safety and preventing damage. Manual transmissions are heavy and awkward, requiring a transmission jack for controlled lowering and raising.

Never attempt to support the transmission solely with floor jacks or makeshift supports. Ensure the vehicle is securely supported on jack stands before beginning any work. Position the transmission jack correctly, distributing the weight evenly.

Slow, controlled movements are essential. Always double-check stability before releasing any support points.