21 circuit wiring harness instructions

Harnesses simplify vehicle wiring, offering a pre-assembled solution with labeled, color-coded wires for easier installation and troubleshooting of circuits.

These kits, like the EZ-21, include fuses, relays, and high-temp wire, ideal for classic cars, hot rods, and custom builds, streamlining electrical projects.

What is a 21 Circuit Wiring Harness?

A 21 circuit wiring harness is a pre-assembled electrical system designed to simplify vehicle wiring. It contains 21 individual circuits, each protected by a fuse, and is equipped with relays for higher-current applications.

These harnesses, such as the EZ-21, feature GXL 125 wire, known for its resistance to grease, oil, gas, and acid. Crucially, each wire is labeled every 5-6 inches along its entire length, facilitating easy circuit identification.

Color-coding further enhances usability, making installation and troubleshooting significantly easier. They are commonly used in classic car restorations, hot rods, and custom vehicle builds, offering a complete wiring solution.

Benefits of Using a 21 Circuit Harness

Employing a 21 circuit wiring harness offers substantial advantages over traditional wiring methods. Installation becomes “EZier,” reducing labor time and potential errors thanks to pre-labeled and color-coded wires.

Troubleshooting is also simplified; the continuous labeling allows for quick circuit tracing. The GXL 125 wire ensures durability and resistance to harsh under-hood conditions.

These harnesses provide a complete, organized system, eliminating the need to source individual components. They are ideal for complex builds, offering a reliable and efficient electrical foundation for any vehicle project, from restorations to race cars.

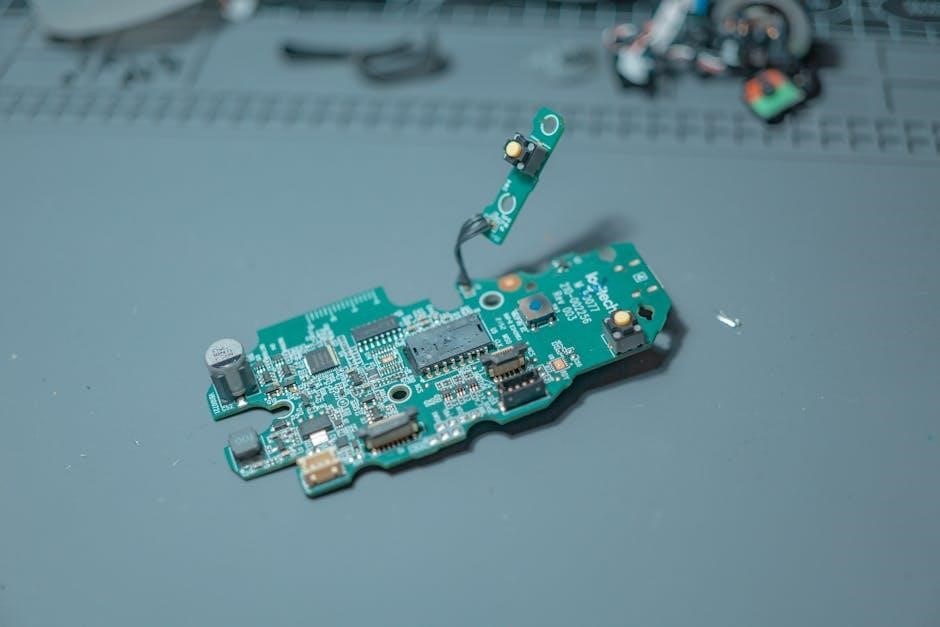

Understanding the Components

21 circuit harnesses include a fuse box, relays for managing high-current devices, and GXL 125 wiring, ensuring a robust and organized electrical system.

Fuse Box and Fuse Selection

The fuse box serves as the central protection point for all circuits within the 21 circuit wiring harness. Kits like the EZ-21 typically include 18 fuses, but selecting the correct amperage is crucial for safety and functionality.

Always consult the wiring diagram and circuit descriptions printed on each wire to determine the appropriate fuse size for each specific application. Using a fuse with a higher amperage than recommended can lead to wire damage or even a fire, while a lower amperage fuse will cause nuisance tripping.

Proper fuse selection safeguards the vehicle’s electrical system and ensures reliable operation of all connected components.

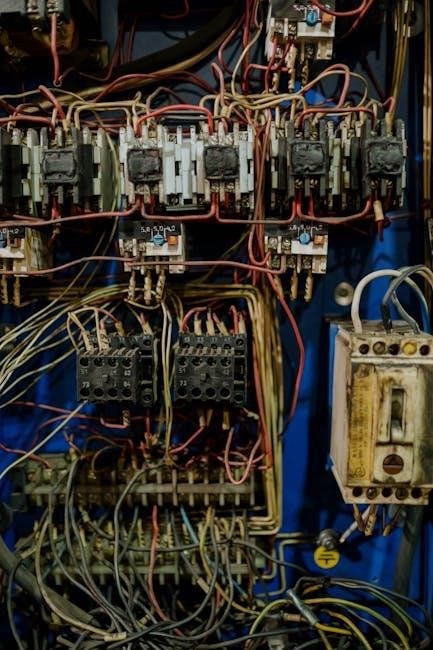

Relays: Function and Placement

Relays are essential components within a 21 circuit wiring harness, acting as electrically operated switches that control high-current circuits with a low-current signal. They protect the main wiring and switches from overload.

Aeroflow universal wiring harnesses include relays, and strategic placement is key. Mount relays close to the power source and the devices they control to minimize wiring length and voltage drop.

Ensure relays are securely mounted and protected from the elements. Proper relay function ensures reliable operation of headlights, horns, fuel pumps, and other high-demand accessories.

Wire Types: GXL 125 and Alternatives

GXL 125 is a premium wire commonly found in 21 circuit wiring harnesses, known for its durability and resistance to harsh conditions. Its cross-linked polyethylene jacket provides excellent protection against grease, oil, gas, and acid, ensuring long-lasting performance.

While GXL 125 is preferred, alternatives exist. Standard PVC-insulated wire can be used in less demanding applications, but lacks the same level of protection.

Choosing the right wire type is crucial for safety and reliability. EZ Wiring kits consistently utilize GXL 125 for its superior qualities, guaranteeing a robust and dependable electrical system.

Installation Process: Step-by-Step

Begin by preparing the vehicle, then mount the fuse box and relays securely. Carefully route the wiring harness, connecting each labeled wire to its designated circuit.

Preparing the Vehicle for Installation

Before starting, disconnect the vehicle’s battery to prevent shorts. Thoroughly inspect the existing wiring, noting any damaged or corroded sections that need attention. Clear a workspace, ensuring ample room to route the new harness.

Plan the harness route, identifying optimal paths avoiding heat sources and moving parts; Consider mounting locations for the fuse box and relays, ensuring accessibility for future maintenance. Gather necessary tools, including wire strippers, crimpers, and a multimeter.

It’s crucial to understand that ground wires aren’t typically included in the kit; black wire is recommended for grounding to avoid confusion with the color-coded system.

Mounting the Fuse Box and Relays

Securely mount the fuse box in an accessible, dry location, away from direct heat. Use appropriate hardware to prevent movement during vehicle operation; Relays should be mounted near the components they control, minimizing wire length.

Ensure adequate ventilation around relays to prevent overheating. Consider using relay brackets for a clean and organized installation. Double-check all mounting points for stability before proceeding.

Remember, the harness is designed for various vehicles, so adaptability in mounting is key. Proper mounting ensures reliable operation and simplifies future troubleshooting.

Routing the Wiring Harness

Carefully route the wiring harness, avoiding sharp bends, moving parts, and potential heat sources like the exhaust. Secure the harness with zip ties or clamps every 12-18 inches to prevent chafing and vibration damage.

Follow the vehicle’s existing wiring channels whenever possible for a cleaner installation. Maintain adequate clearance between the harness and any fuel lines or hot engine components.

The labeled wires in the harness simplify tracing circuits during routing. Ensure sufficient slack is left at connections to accommodate chassis flex and movement.

Decoding the Wiring Diagram

Diagrams utilize color coding and labeled wires, often every 6-5 inches, to identify each circuit for installation and future troubleshooting needs.

Color Coding System Explained

Color coding within a 21 circuit wiring harness is a crucial element for simplified installation and efficient troubleshooting. Manufacturers, like EZ Wiring and Aeroflow, employ distinct colors to designate specific circuits. While the exact color assignments can vary, the system aims for intuitive identification.

Understanding that diagrams may only show a color or a label – not both – is key. Remember, ground wires are typically not provided within the kit; black is recommended for grounding, and white for labeled black harnesses. GM wiring often uses a color-coded system alongside schematic diagrams and printed circuit descriptions on the wires themselves, aiding in identification during installation and future modifications.

Wire Labeling and Identification

Wire labeling is a cornerstone of user-friendly 21 circuit wiring harnesses, significantly easing installation and future diagnostics. EZ Wiring, for example, labels each wire every 5 inches along its entire length, ensuring constant circuit identification. Aeroflow harnesses feature labeling every 6 inches (152mm).

These labels, combined with the color coding, provide a dual-system for clarity. The printed circuit numbers and descriptions directly on the wire itself, alongside schematic diagrams, allow for easy tracing and understanding of each circuit’s function. This detailed labeling makes troubleshooting significantly easier, even after modifications.

Understanding Circuit Numbers and Descriptions

Circuit numbers and descriptions are vital for successful 21 circuit wiring harness installation and maintenance. These are typically printed directly onto the wire itself, complementing the color-coding and labeling systems. GM wiring utilizes this method, alongside schematic diagrams, for easy identification.

Understanding these details allows installers to quickly determine the function of each wire – whether it’s for headlights, the fuel pump, or the ignition coil. This information is crucial during installation and invaluable when adding future accessories or diagnosing electrical issues within the vehicle’s system.

Troubleshooting Common Issues

Diagnosing problems involves checking for blown fuses, testing relay functionality, and carefully tracing wire connections using the harness’s labeling and diagrams.

Identifying Blown Fuses

Blown fuses are a common issue in any electrical system, and a 21-circuit harness is no exception. When troubleshooting, the first step is always to inspect the fuse box. Visually examine each fuse; a broken filament within the clear plastic indicates a blown fuse.

The EZ Wiring system utilizes 18 fuses within the EZ-21 kit, so methodical checking is crucial. Remember that the wiring harness provides the fuses, but doesn’t include ground wires – these are typically black. Replacing a blown fuse with one of the correct amperage is essential for safety and proper circuit function.

Diagnosing Relay Failures

Relays are vital components within a 21-circuit harness, controlling higher-current devices. Diagnosing a relay failure begins with verifying power to the relay coil. If power is present, but the relay isn’t clicking, the relay itself is likely faulty and needs replacement.

Aeroflow universal wiring harnesses include relays, simplifying the process. Ensure the replacement relay matches the original’s specifications. A multimeter can test relay continuity. Remember, proper circuit identification, aided by color coding and labeling every 6 inches, is key to pinpointing the affected relay within the harness.

Tracing Wire Connections

Tracing wire connections in a 21-circuit harness is significantly simplified by the labeling and color-coding features. EZ Wiring kits label each wire every 5 inches along its entire length, making circuit identification straightforward. Follow the labeled wire from the device back to the fuse box or relay.

Utilize wiring diagrams alongside the physical labels. Remember that ground wires aren’t typically included in the kit; black wire is recommended for grounding. GM color-coded wires, combined with circuit numbers, further aid in tracing. This systematic approach ensures accurate connection verification.

Grounding and Electrical Safety

Proper grounding is crucial for electrical system function and safety; use black wire for grounds. Ensure secure connections to the chassis for optimal performance.

Importance of Proper Grounding

Establishing a solid grounding system is paramount for the safe and reliable operation of your vehicle’s electrical components when utilizing a 21-circuit wiring harness. A poor ground can lead to a multitude of issues, including erratic electrical behavior, component failure, and even potential fire hazards.

The chassis serves as the primary ground point, and all connections must be clean, tight, and free of corrosion. Utilizing a dedicated ground wire, often black in color, ensures a low-resistance path for current to return to the source. Remember, the harness itself doesn’t typically provide ground wires; these are separate additions.

Consistent grounding prevents voltage drops and ensures that each circuit functions as intended, safeguarding both the wiring harness and the connected accessories.

Recommended Ground Wire Gauge and Color

For optimal performance and safety with your 21-circuit wiring harness, selecting the correct ground wire gauge is crucial. A minimum of 12-gauge wire is generally recommended for most applications, ensuring sufficient current-carrying capacity. However, for high-demand circuits or longer runs, upgrading to 10-gauge wire provides an added margin of safety.

While the harness kit doesn’t supply ground wires, black is the universally accepted color for grounding connections, minimizing confusion during installation and future troubleshooting. Alternatively, white can be used on labelled black harnesses.

Consistent color-coding simplifies identification and maintenance, contributing to a reliable and organized electrical system.

Specific Applications

These versatile 21-circuit harnesses excel in classic car restorations, hot rod builds, and custom vehicle projects, providing a complete wiring solution.

They simplify electrical upgrades for various automotive applications, offering convenience and reliability.

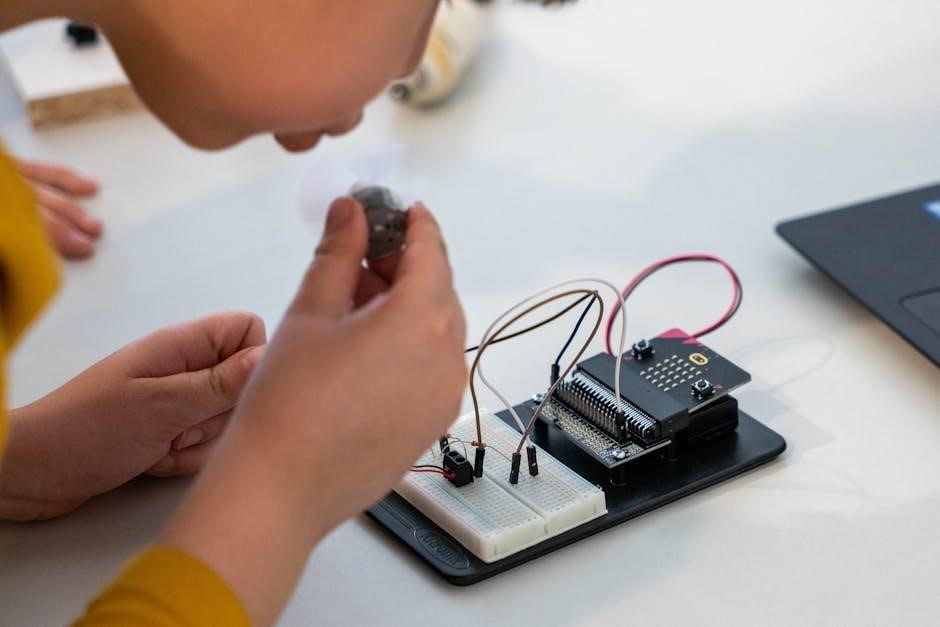

Classic Car Wiring Upgrades

Upgrading the electrical system in a classic car with a 21-circuit harness offers significant improvements over aged, often brittle, original wiring. These harnesses provide a modern, reliable foundation, addressing common issues like shorts and corrosion;

The pre-labeled and color-coded wires simplify installation, even for those unfamiliar with vintage car wiring diagrams. Replacing the entire system ensures compatibility with modern accessories like upgraded audio systems or electronic ignition.

EZ Wiring kits are specifically designed for this purpose, offering a complete solution that enhances safety and functionality while preserving the classic vehicle’s integrity.

Hot Rod and Race Car Wiring

For hot rods and race cars, a 21-circuit wiring harness is crucial for building a reliable and performance-focused electrical system. These vehicles often require numerous circuits to support aftermarket components like fuel injection, data loggers, and electronic transmissions.

Universal harnesses from brands like Aeroflow provide a flexible solution, allowing customization to meet specific needs. The color-coded and labeled wires simplify installation within the confined spaces of a race car chassis.

Prioritizing high-quality, heat-resistant wiring, like GXL 125, is essential for durability and safety in demanding racing environments.

Custom Vehicle Wiring Solutions

When undertaking custom vehicle builds, a 21-circuit wiring harness offers unparalleled flexibility. These harnesses accommodate unique electrical requirements beyond standard automotive setups, supporting custom lighting, audio systems, and specialized equipment.

The pre-labeled and color-coded wires significantly reduce wiring complexity, allowing builders to focus on fabrication and design. EZ Wiring kits, for example, are designed for diverse applications, from street rods to one-off creations.

Careful planning and a detailed wiring diagram are vital to ensure proper circuit allocation and functionality in these individualized projects.

EZ Wiring Harness Specifics

EZ-21 harnesses feature labeled wires every five inches, color-coding for easy identification, and include 18 fuses, simplifying installation and troubleshooting significantly.

EZ-21 Harness Features

The EZ-21 harness distinguishes itself through several key features designed to simplify automotive wiring projects. Each wire within the harness is meticulously labeled at five-inch intervals along its entire length, ensuring effortless circuit tracing and identification during installation and future maintenance.

Furthermore, a vibrant color-coding system complements the labeling, providing an additional layer of clarity. This kit boasts 18 fuses, accommodating a wide range of vehicle electrical needs. Constructed with GXL 125 wire, it offers superior resistance to grease, oil, gas, and acids, guaranteeing durability and reliability in harsh under-hood environments.

The EZ Wiring system truly embodies its name, making wiring easier and troubleshooting significantly more manageable for both novice and experienced enthusiasts.

EZ Wiring Labeling System

EZ Wiring’s labeling system is a cornerstone of its user-friendly design, drastically simplifying the wiring process. Each wire is clearly marked with both a color code and a printed circuit number and description directly on the wire jacket. This dual-identification method ensures accurate connections and minimizes guesswork during installation.

The system is designed to work seamlessly with GM color-coded wires and accompanying schematic diagrams, providing a comprehensive guide for identifying circuits. Importantly, the kit does not include ground wires; black wire is recommended for grounding, and white for labeled black harnesses.

This meticulous labeling approach streamlines troubleshooting and future modifications, making electrical work accessible to all skill levels.

Additional Resources

Wiring diagrams and supportive online communities offer valuable assistance for installation and troubleshooting. Forums provide a platform for shared knowledge and expert advice.

Where to Find Wiring Diagrams

Locating accurate wiring diagrams is crucial for successful installation. EZ Wiring, Inc. provides diagrams specifically for their harnesses, like the EZ-21, ensuring compatibility. Remember that diagrams may indicate wires not included in the kit, such as ground wires – typically black or white.

GM color-coded wire schematics, alongside printed circuit numbers and descriptions on the wire itself, are also helpful resources. These assist in identifying circuits during installation and future modifications. Online forums and manufacturer websites often host downloadable diagrams and support documentation for various 21 circuit wiring harness applications.

Online Forums and Support Communities

Engaging with online communities offers invaluable support during 21 circuit wiring harness installation. Forums dedicated to classic cars, hot rods, and custom vehicle builds frequently feature threads discussing wiring challenges and solutions.

These platforms allow you to connect with experienced enthusiasts who can provide guidance, troubleshoot issues, and share helpful tips. Searching for specific keywords related to your vehicle and harness model will yield relevant discussions. Many manufacturers, like EZ Wiring, also maintain online support resources and actively participate in these communities.